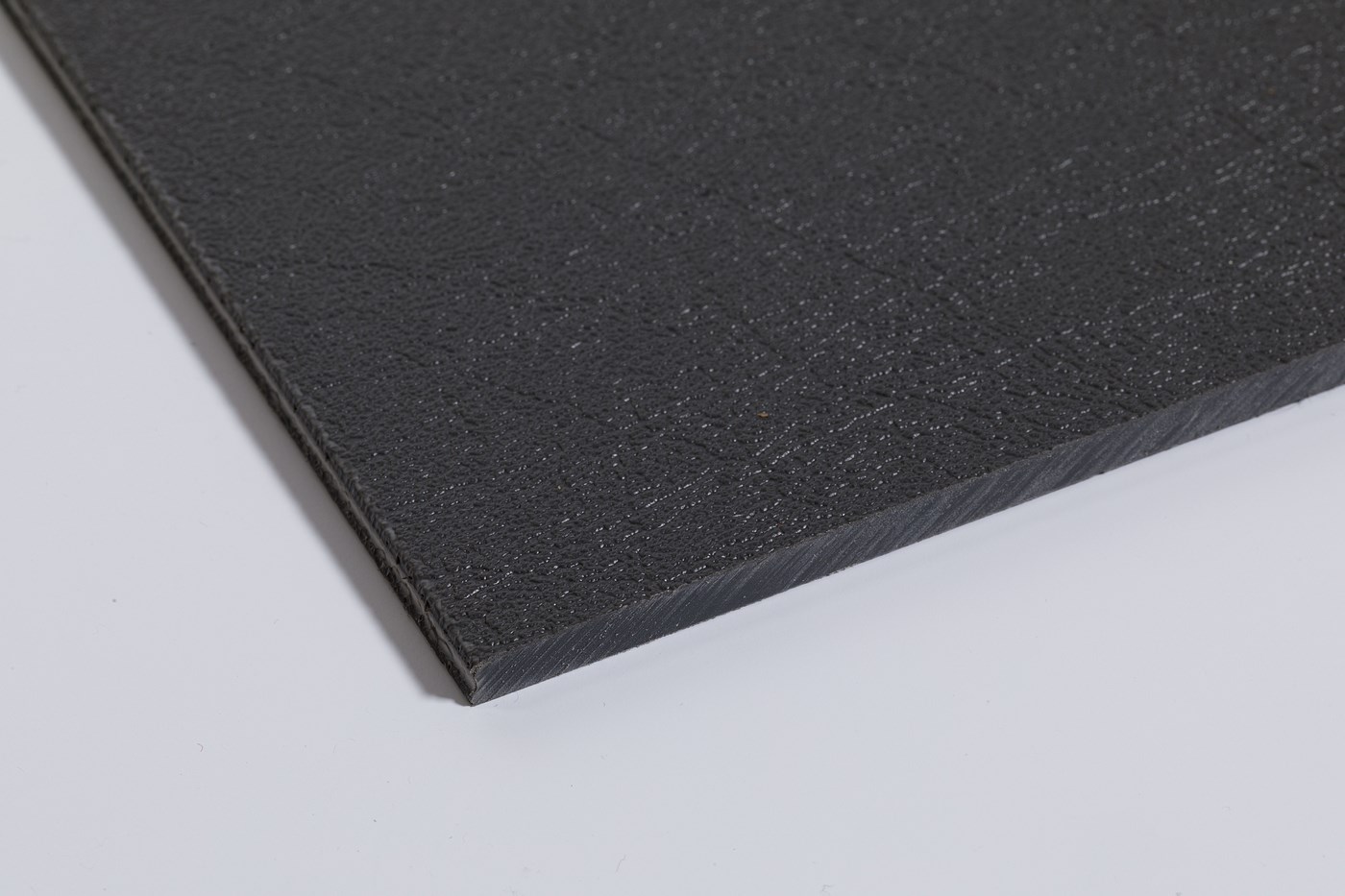

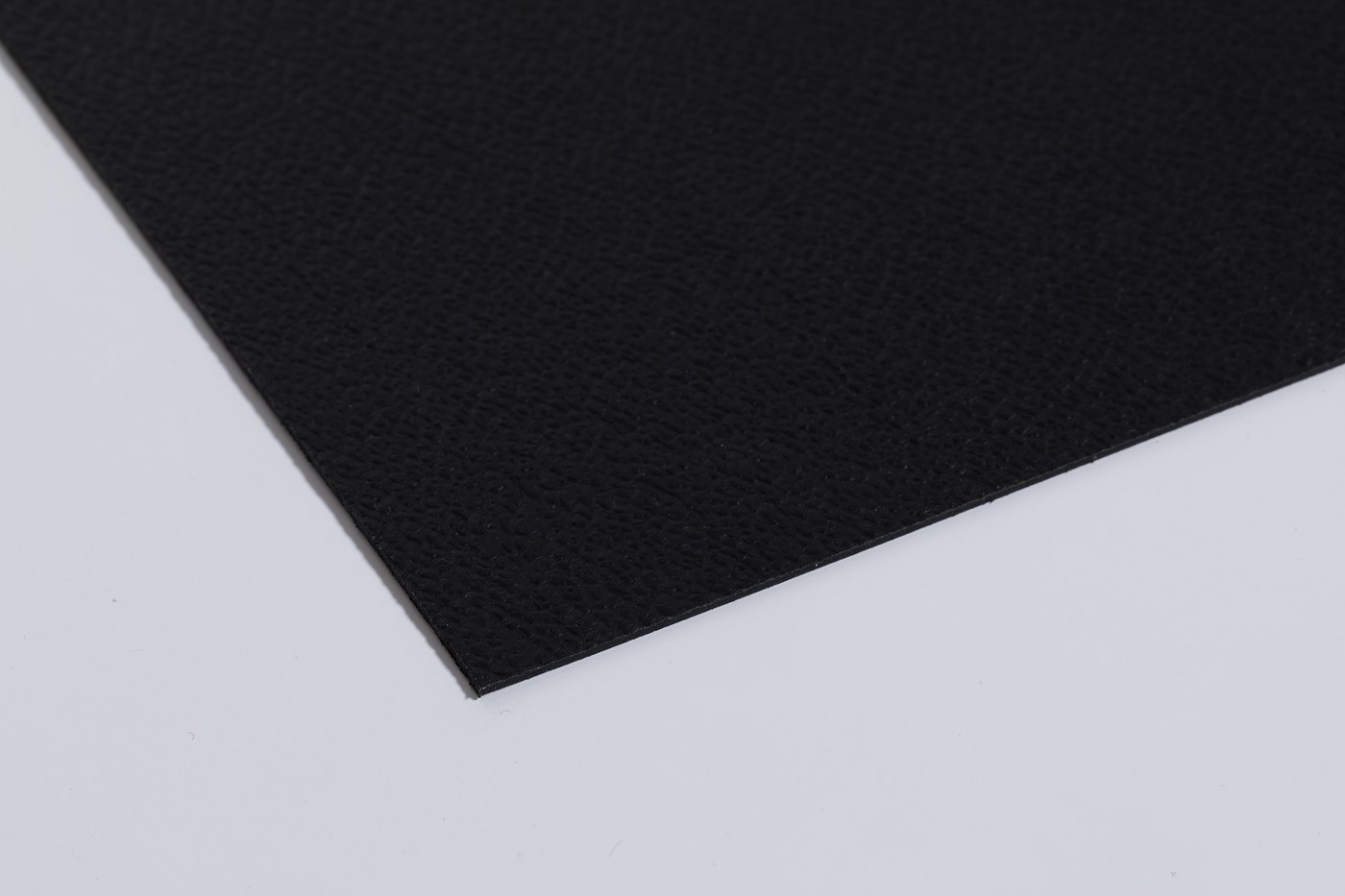

ABS / TPU plastic sheets are sheets with a combination of a soft surface layer with a soft-touch effect of thermoplastic polyurethane (TPU) and an impact-resistant layer of acrylonitrile butadiene styrene (ABS). Polyurethane provides products with high wear resistance, scratch resistance, resistance to gasoline and engine oils. The bottom layer of ABS is responsible for high-quality forming and high impact resistance, even at low operating temperatures.Parts made of ABS / TPU sheet have an aesthetic matte (anti-reflective), pleasant surface. The hardness of the top layer can be different depending on the customers’ requirements.

ABS/TPU plastic sheets are available in various colors and shades.

ABS/TPU sheets have good UV protection making them suitable for outdoor use.

We produce TPU sheets with a thickness of 2 to 10 mm for seals and cuffs production, gasket material for drainage systems, lining of various containers, conveyor belts. TPU sheets are characterized by high elasticity even at low temperatures, high resistance to abrasion and bending and tearing.

or special purposes, we produce sheets with high dissipative and antistatic properties with a specific volume resistance of 103-108 Ohm*m in black.

Application area

- Interior trim parts for cars and buses

- Trays for railway and air transport

- Finishing and facing materials

- Inner surfaces of car trunk

Processing methods

- Pneumatic vacuum forming

- Machining

- Welding

- Gluing

Delivery form

- Thickness: 1-6mm

- Width: up to 1560 mm

- Smooth or embossed (“leather”)

- The surface is glossy, matt

Chemical properties

Resistant:

- To water

- To sea water

- To gasoline

- To diesel fuel

- To kerosene

- To mineral oils

- To waterless lubricants

Not resistant:

- To organic acids

- To alkaline solutions

- To concentrated inorganic acids

- To halogenated hydrocarbons

- To ketones

- To complex esters

- To alcohols

Operating temperature

- Maximum temperature of long-term operation: 75-80 °С

- Withstands short-term heating up to 90-100 °С

Flammability indicators

- Ignites under the influence of a flame or when an appropriate amount of heat is supplied

- Burns brightly and unstably after being removed from the flame with a strong formation of soot

- Spontaneous combustion at 350 °С

- Ignition from an external source at 450 °С

Characteristics of ABS / TPU plastic sheet

| Units | Testing Method, ISO | Value | ||

|---|---|---|---|---|

| Density | g/sm3 | 1183 | 1.06 | |

| Tensile yield strength | MPa | 527 | 28 | |

| Elongation at break | % | 527 | 10 | |

| Charpy impact strength on sample without notch (rib) | 23°С | kJ/m2 | 179 | н/р |

| Charpy impact strength on sample without notch (rib) | -20°С | kJ/m2 | 179 | н/р |

| Abrasion resistance | On a sample d 100 mm abrasive wheel H18 pressing force 500 g | g | 0,05 | |

| Vicat softening point | 50Н/50°С | °С | 306/В120 | 98 |

| Bending temperature under load, не менее | 1,8 MPa | °С | 75-2Ае | 95 |

* The above values refer to the state of the thermoplastics immediately after extrusion and do not take into account the effects of aging.

* The properties of the sheet may vary depending on the properties of the raw materials used

«Typical malfunctions during thermoforming and their elimination methods» you can download here

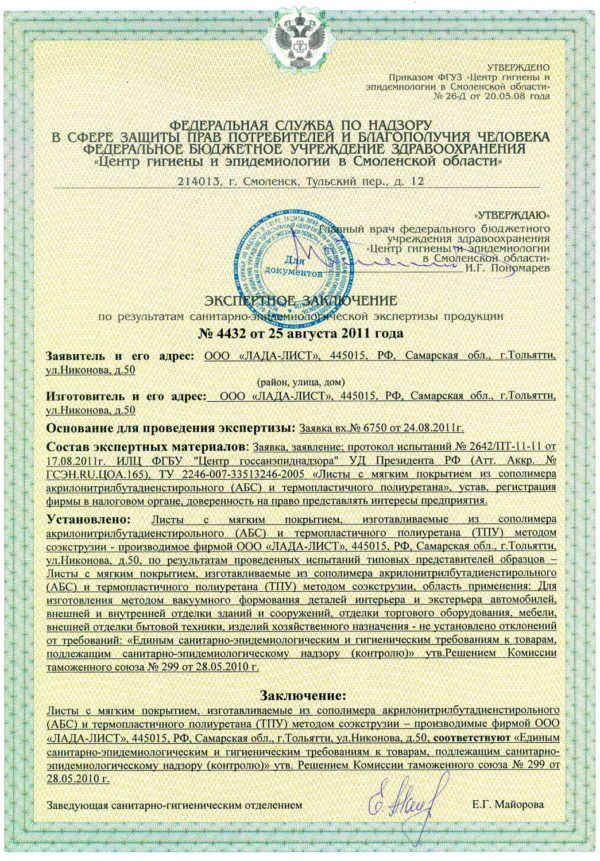

Certificates

CALL US

8 (800) 770-05-52 (free within the Russian Federation)

Togliatti

+7 (8482) 69-10-20

+7 (8482) 69-10-30

+7 (8482) 69-10-31

Moscow

+7 (926) 838-75-93

+7 (915) 176-38-87

Rostov-on-Don

LEAVE AN APPLICATION ONLINE

You can also order plastic sheets

by filling out the detailed online order form on our website.

Additional Information

ABS/TPU plastic sheet is a multi-layer sheet with a soft surface layer of a mixture of thermoplastic polyurethane (TPU) and acrylonitrile-butadiene-styrene (ABS) which provides high wear resistance, scratch resistance, resistance to gasoline and machine oils. The bottom layer of ABS provides the sheets with high-quality molding and high impact resistance, resistance to low temperatures. Parts made of ABS / TPU sheet have a matte (anti-reflective), pleasant to the touch surface. ABS / TPU plastic sheet is available in various colors and shades.

- very good abrasion and scratch resistance

- anti-slip properties and noise reduction

- has so-called Soft effect (due to TPU coating layer)

- good strength and ductility at low temperatures

- excellent chemical resistance in contact with oils, hydrocarbons and many solvents (better than ABS)

- good resistance to hydrolysis to contact with microorganisms (bacteria, fungi, etc.)

- slight deformation under load and high compressive strength

- high resistance of the cut material to further tearing

- the possibility of obtaining a surface with varying degrees of gloss / haze

- the ability to obtain slabs with antistatic surface properties (resistance up to 105Ω)

- extrusion capability with recycled ABS

Nowadays TPU / ABS is most widely used in the automotive industry as a material for thermoformed interior parts of cars, buses and automotive vehicles, external trunks. Due to its mechanical strength, it is used for the production of suitcases, trays for transportation, the manufacture of trays for railway and air transport, finishing and cladding works, so they can be easily revetted on any surface, including the facades of residential and industrial buildings. They make excellent and durable advertising and information stands, shop windows, partitions in public buildings.