Polypropylene sheet is produced by flat-slot extrusion from granules obtained by propylene polymerization. It is a plastic sheet with a wide range of applications. Nowadays it is the most demanded modern plastic due to its excellent consumer properties and versatility of use and the lowest density of all thermoplastics.

From polypropylene homopolymer, where macromolecules contain the same monomer units, sheets are obtained with high bending strength and operating temperatures from -5 to +105 degrees.

A block copolymer of propylene with ethylene (copolymer) is used to produce sheet plastics with high impact resistance (at low temperatures), which have increased long-term thermal stability and resistance to thermal oxidative destruction during operation. The operating temperature of products from such sheets is from -40 to +80 degrees.

High climatic and chemical resistance to various aggressive environments, water and corrosion resistance makes polypropylene sheets indispensable in the manufacture of various containers and galvanic baths, ventilation systems. The impact resistance of this plastic allows you to make products from it for outdoor use at subzero temperatures. Polypropylene plastic sheet is non-toxic and approved for use in contact with food.

To prevent destruction from solar radiation, the polymer must be enriched with uv light stabilizers and antioxidants.

Special purposes polypropylene plastic sheets with a specific volume resistance of 103-108 Ohm*m can be produced in black color.

Our company produces foamed or porous polypropylene – a sheet polypropylene with special additives in the middle. They make the structure of the material fine-meshed. The result is polypropylene with a monolithic top and bottom layer, and is foamed inside. Such sheets have a lower density and weight and, accordingly, a more favorable cost. Sheets are well mechanically processed and welded.

For lining and better adhesion of polypropylene plastic sheets to concrete and metal surfaces, we produce custom-made polypropylene sheets laminated (duplicated) with polyester fabric or fiberglass. The fabric is applied during sheet extrusion and serves as an adhesive layer for polyester or epoxy resin adhesives.

Application area

- Galvanic baths

- Grease traps, septic tanks

- Tanks, reservoirs

- Sediment tanks, storage

- Pools, fonts

- Air ducts

- Reusable formwork

- Cutting boards, storage containers

- Cellars

Processing methods

- Mechanical processing (cutting, sawing, drilling)

- Laser cutting, etc.

- Molding

- Contact welding, ultrasonic, gun, extruder

- Bending

Delivery form

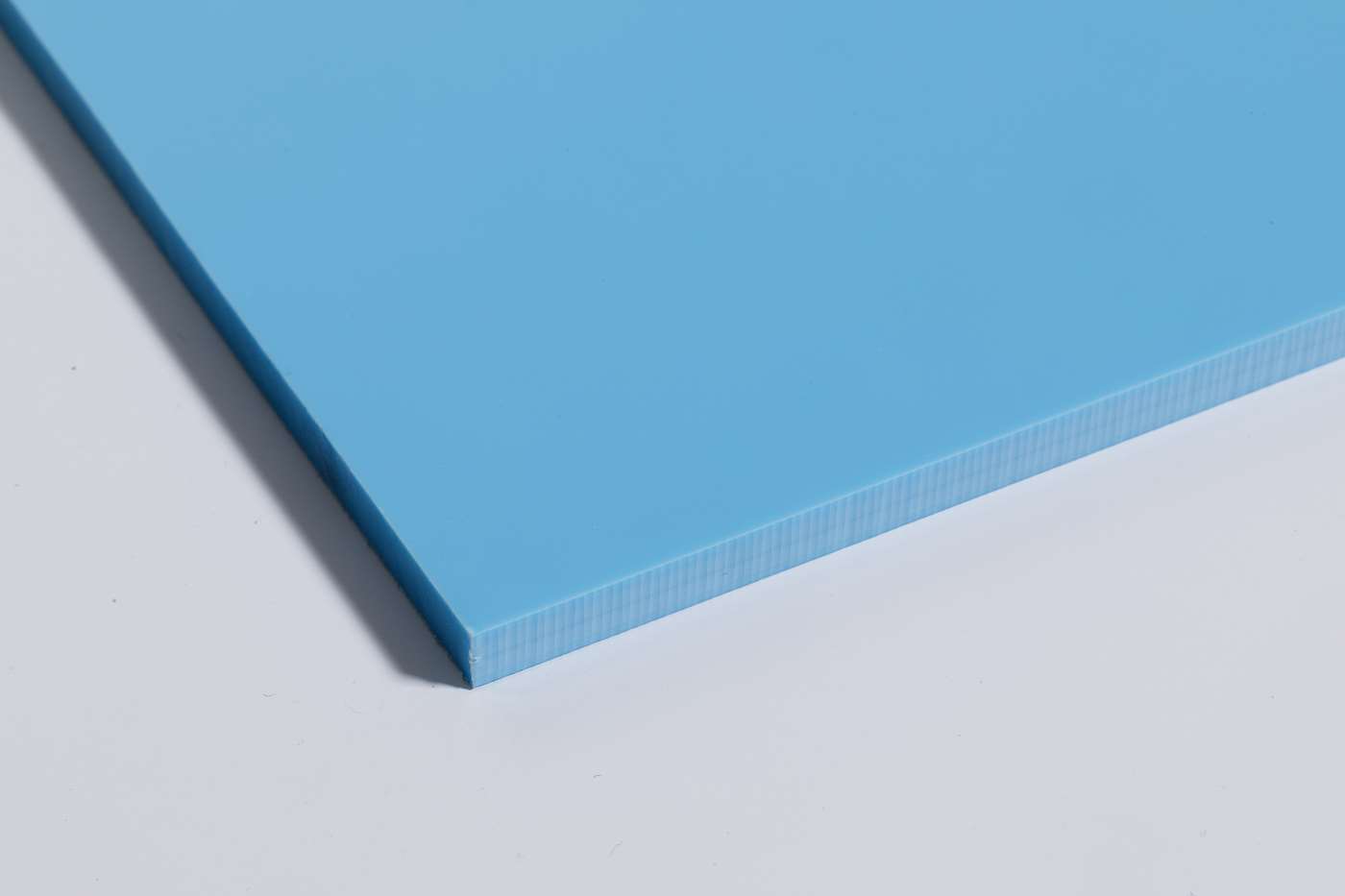

- Thickness from 1.0-30 mm

- Width up to 2100mm

- The relief is smooth

- The surface is protected with PE foil on one or both sides

Chemical properties

Resistant:

- To organic solvents

- To alcohols

- To complex esters

- To ketones

- To mineral and vegetable oils

Not resistant:

- To chlorosulfonic acid

- To concentrated sulfuric acid

- To concentrated nitric acid

- To chrome mix

Operating temperature

Polypropylene and polyethylene in accordance with GOST 12.1.044 are combustible products, in contact with an open fire they burn with a smoky flame. Ignition temperature of polypropylene (325-343) °C, autoignition (325-388) °C (GOST 12.1.041). Ignition temperature of polyethylene 306 °C, self-ignition 417 °C (GOST 12.1.041)

Flammability indicators

- Burns up under the influence of a flame or due to an appropriate heat amount

- Burns with a smoky flame in contact with an open fire

- Self-ignition at a temperature (325-388) °C

- Ignition temperature (325-343) °C

Characteristics of polypropylene sheet

| Units | Testing Method, ISO | Value | ||

|---|---|---|---|---|

| Density | g/sm3 | 1183 | 0.92 | |

| Tensile yield strength | MPa | 527-2/1В/20 | 23 | |

| Elongation at break | % | 527 | 750 | |

| Charpy impact strength on sample without notch (rib) | 23°С | kJ/m2 | 179/1fU | н/р |

| Charpy impact strength on notched specimen (ribbed) | 23°С | kJ/m2 | 179/1ерА | 50 |

| Charpy impact strength on sample without notch (rib) | -40°С | kJ/m2 | 179/1fU | н/р |

| Charpy impact strength on notched specimen (rib) | -40°С | kJ/m2 | 179/1ерА | 7 |

| Flexural modulus, не менее | MPa | 178 | 1200 | |

| Bending temperature under load | 1,8 MPa | °С | 75-2Ае | 55 |

| 0,45MPa | °С | 75-2Ве | 115 | |

| Vicat softening point | 50Н/50°С | °С | 306/В50 | 80 |

| Vicat softening point | 10Н/50°С | °С | 306/А50 | 156 |

| Shore hardness | Method D | 868 | 69 |

* The above values refer to the state of the thermoplastics immediately after extrusion and do not take into account the effects of aging.

* The properties of the sheet may vary depending on the properties of the raw materials used.

«Chemical resistance of polypropylene to various liquids» you can download here

CALL US

8 (800) 770-05-52 (free within the Russian Federation)

Togliatti

+7 (8482) 69-10-20

+7 (8482) 69-10-30

+7 (8482) 69-10-31

Moscow

+7 (926) 838-75-93

+7 (915) 176-38-87

Rostov-on-Don

LEAVE AN APPLICATION ONLINE

You can also order plastic sheets

by filling out the detailed online order form on our website.

Additional Information

Polypropylene is a synthetic thermoplastic non-polar polymer belonging to the class of polyolefins, polymerized product of propylene.

Depending on the raw material used, polypropylene sheet is produced in two types:

- PP-S are sheets from a copolymer of propylene and ethylene, used for operation at temperatures from -40 to + 80 °C.

- PP-G are sheets of propylene homopolymer, used for use at temperatures ranging from -5 to + 105 °C.

We also produce electrically conductive polypropylene per customized order.

Our polypropylene sheet has the following positive properties:

- High impact and flexural strength

- Wear resistance

- High moisture resistance

- No toxicity

- Electrically conductive or anti-static

- Excellent chemical resistance to various aggressive media

PP-S characteristics

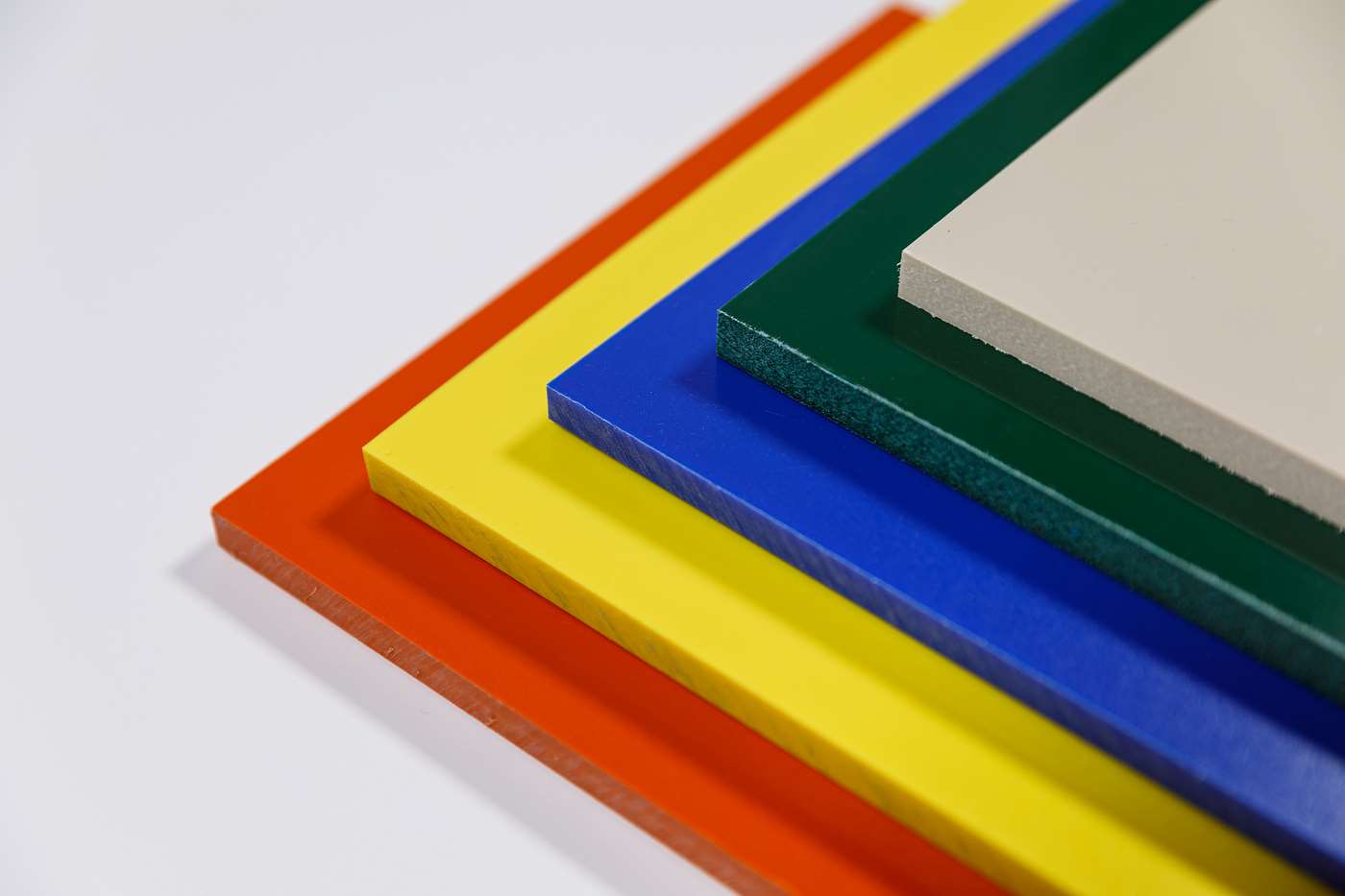

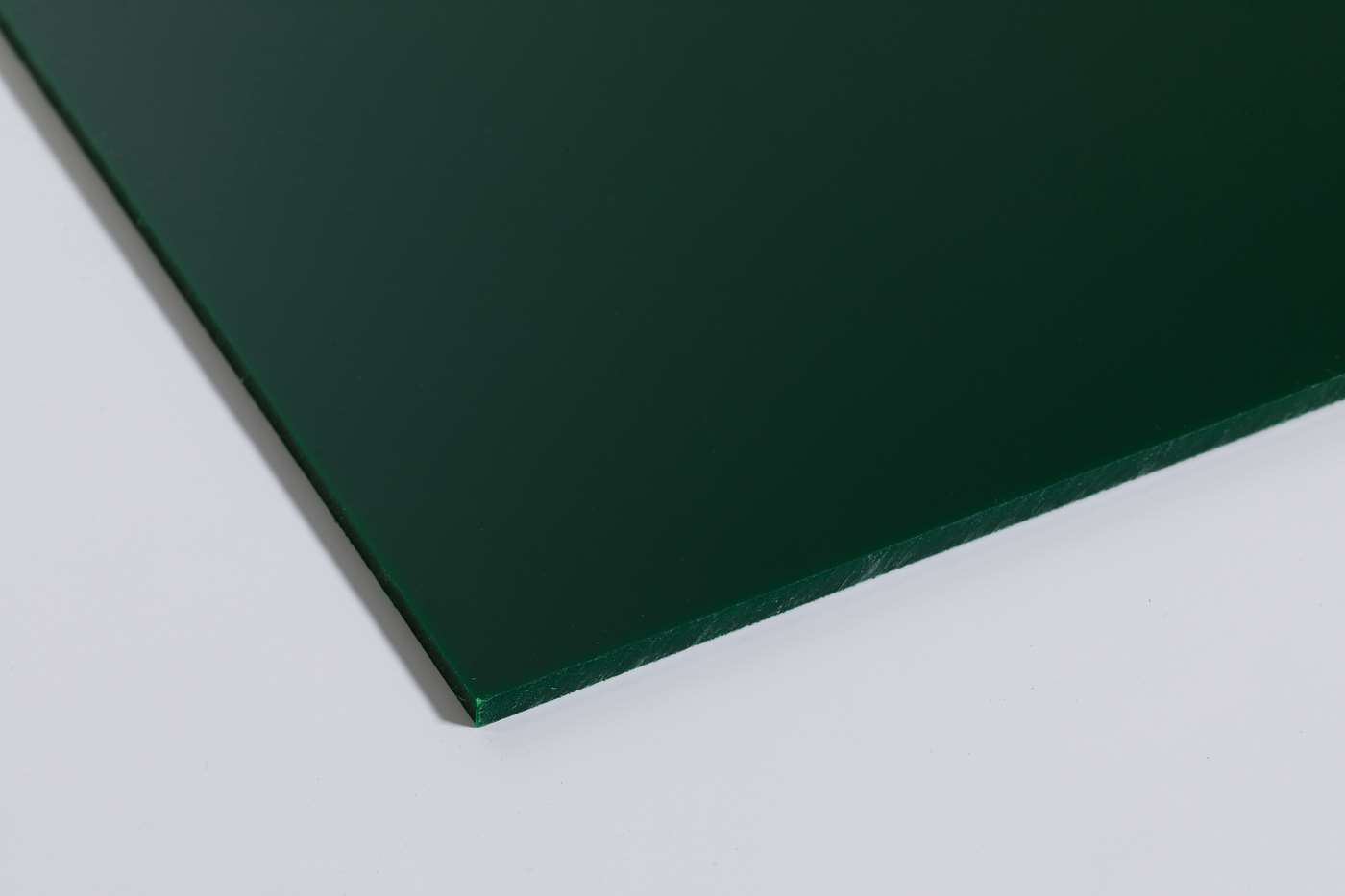

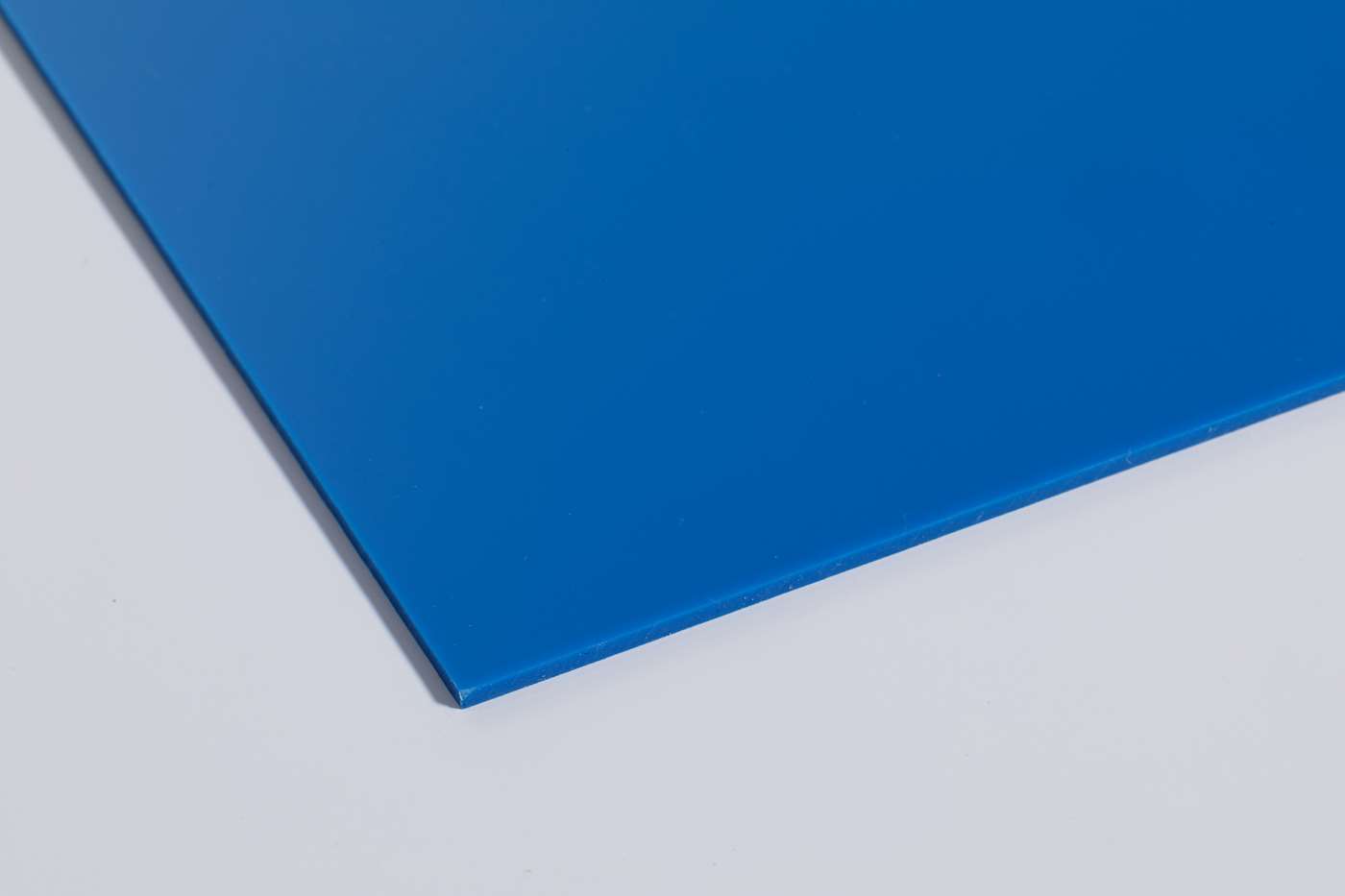

Polypropylene (block copolymer) sheets are characterized by high rigidity, high strength, especially at low temperatures, good resistance to abrasion and stress corrosion cracking. PP is characterized by good electrical insulating properties in a wide temperature range, high chemical resistance and low vapor and gas permeability. The operating temperature of sheet products is from -40 to + 80 °C. Plastic sheets can be produced in various colors, depending on the customer’s requirements. UV stabilization possible.

PP-G characteristics

Polypropylene sheets (homopolymer) are characterized by high impact and bending strength, good resistance to abrasion and stress corrosion cracking. PP is characterized by good electrical insulating properties in a wide temperature range, high chemical resistance and low vapor and gas permeability. The operating temperature of sheet products is from -5 to + 105 °С. Plastic sheets can be produced in various colors, depending on the customer’s requirements. UV stabilization is possible.

Working with sheet polypropylene

In the production of our polypropylene sheet, special dyes with a light resistance of 7-8 points and uv light stabilizers are used, which allow the use of products outdoors without significant changes in size.

Our sheets are good for cutting, milling and machining. Sheets are well welded by ultrasonic and contact methods, a gun, an industrial hair dryer and an extruder. They can be assembled by bolts or rivets.

Our advantages

- We have been in the market for over 25 years.

- We have the largest European-made extrusion equipment park in Russia.

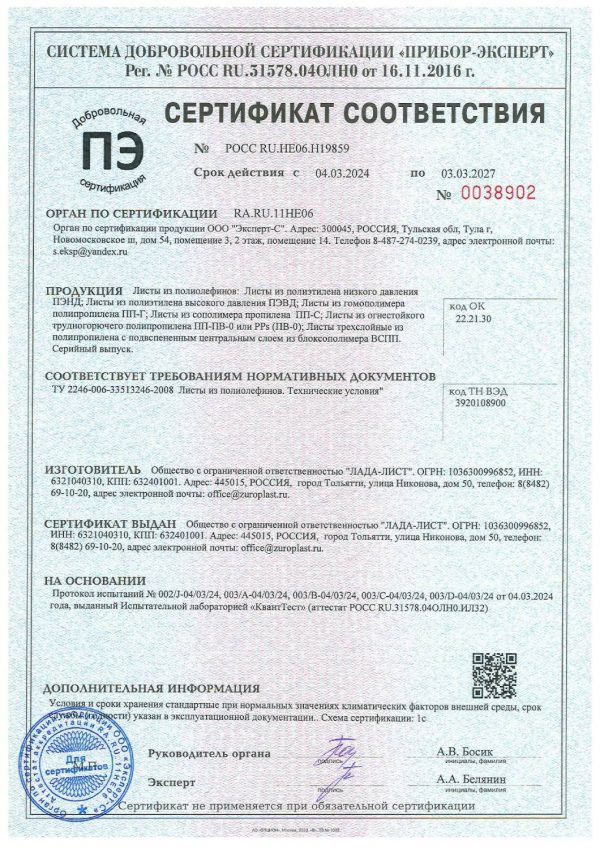

- Compliance with international quality standards.

- Our equipment allows us to manufacture products in increments of 0.05 mm in thickness.

The LADA-LIST company produces and sells polypropylene sheets of its own production. For 25 years of successful work we have produced more than 40,000 tons of products, improved the production process (extrusion method) and earned trust of 200 regular customers.